How a Jet Pump Works

The jet pump works by using the momentum of one fluid to propel another fluid. All jet pumps in the oil and gas industry operate using the same principles.

The JJ Tech Jet Pump is made in the USA using the highest quality materials. Our fluid path design ensures a laminar flow, reducing inefficiencies that can hinder production.

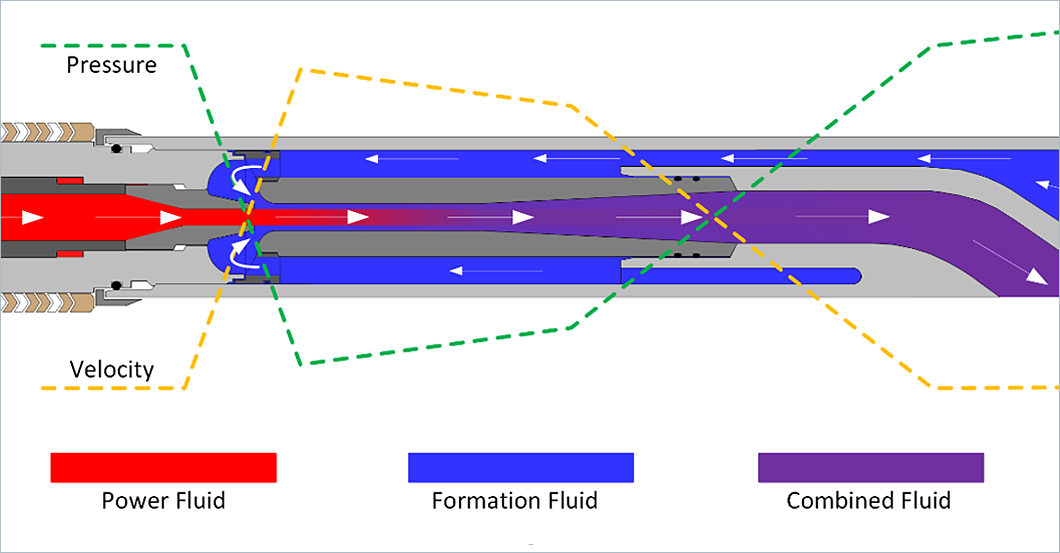

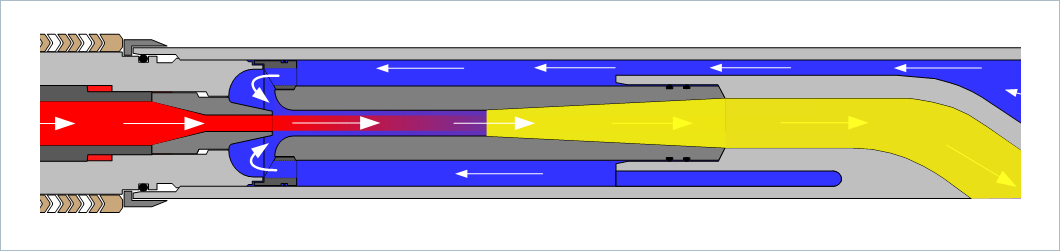

Power fluid, which is produced water or oil, is pumped from the surface at a given flowrate and pressure into the wellhead, down the tubing to the jet pump. This high-pressure liquid is then directed through the nozzle. The resulting pressure drop (Venturi Effect) across the nozzle allows for fluid from the formation (oil or gas zone) to enter the jet pump (intake) and combine with the power fluid in the mixing tube (throat).

Power fluid, which is produced water or oil, is pumped from the surface at a given flowrate and pressure into the wellhead, down the tubing to the jet pump. This high-pressure liquid is then directed through the nozzle. The resulting pressure drop (Venturi Effect) across the nozzle allows for fluid from the formation (oil or gas zone) to enter the jet pump (intake) and combine with the power fluid in the mixing tube (throat).

The combined fluids pass through the diffuser, where the velocity of the fluid reduces as the pressure increases enough to power the fluid to the surface. This pressure drop allows well fluids to flow from the reservoir at the desired production rate into the wellbore and jet.

Downhole Jet Pump Components

The jet pump uses the momentum of one fluid to move another fluid. The JJ Tech jet pump fluid path design ensures highest possible production rate for a given fluid exit velocity.

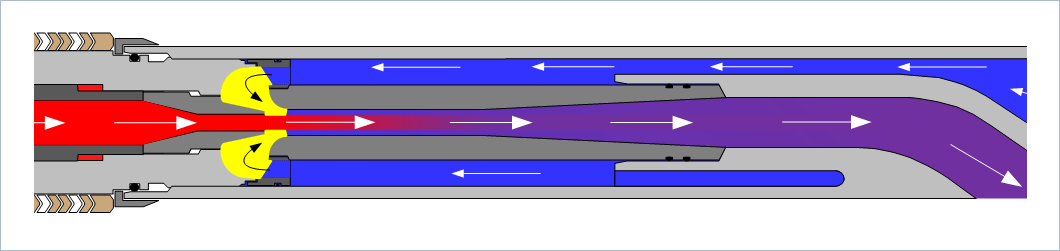

Nozzle

The nozzle increases the velocity and decreases the pressure of the power fluid.

Intake

Lower pressure created by the Nozzle directs the produced fluid to the Intake of the Jet Pump.

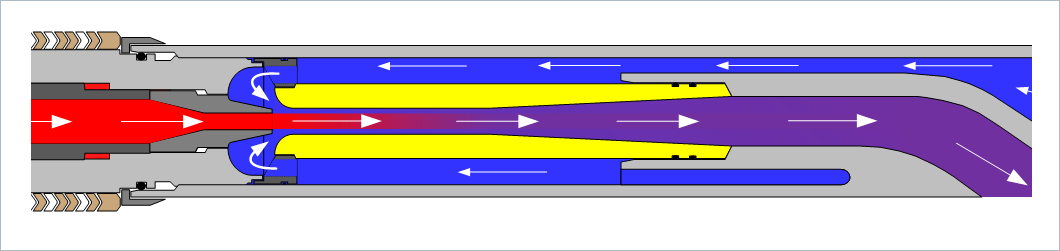

Mixing Tube (Throat)

The power fluid encounters the produced fluid inside the mixing tube, where the diffusion of the combined fluids begins.

Diffuser

The diffuser decreases the velocity while increasing the pressure of the combined fluids. The increase in pressure is needed to lift the combined fluids back to surface.

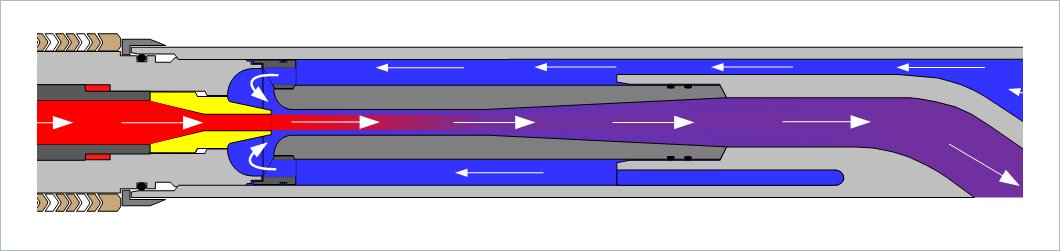

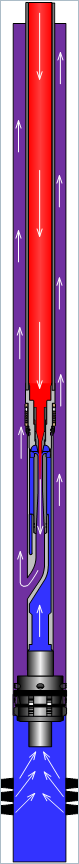

"Standard Flow" Configuration

Power Fluid (Red) is injected into the tubing down to the Nozzle. The resulting pressure drop across the Nozzle allows for Produced Fluid (Blue) to enter the Jet Pump. The Power Fluid and Produced Fluid combine together in the Mixing Tube.

The combined fluids exit the Jet Pump and flow to the surface via the Casing. Jet Pumping can also be in “Reverse Flow” Configuration, Which Power Fluid is injected into the casing and the Combined Fluids return up the Tubing.

Benefits include:

- No workover rig or slickline unit needed for servicing or well production optimization

- Wellbore, flow lines and facilities can be completely chemically treated via jet pump power fluid

- Increased production from deviated, horizontal wells and wellbore restrictions

- Reliability with no downhole moving parts

CONTACT US

Talk to the JJ Tech team and see if our artificial lift solution can help you reduce costs over the life of your wells. Complete the form to see whether our products can optimize your well’s efficiency and lower maintenance costs.